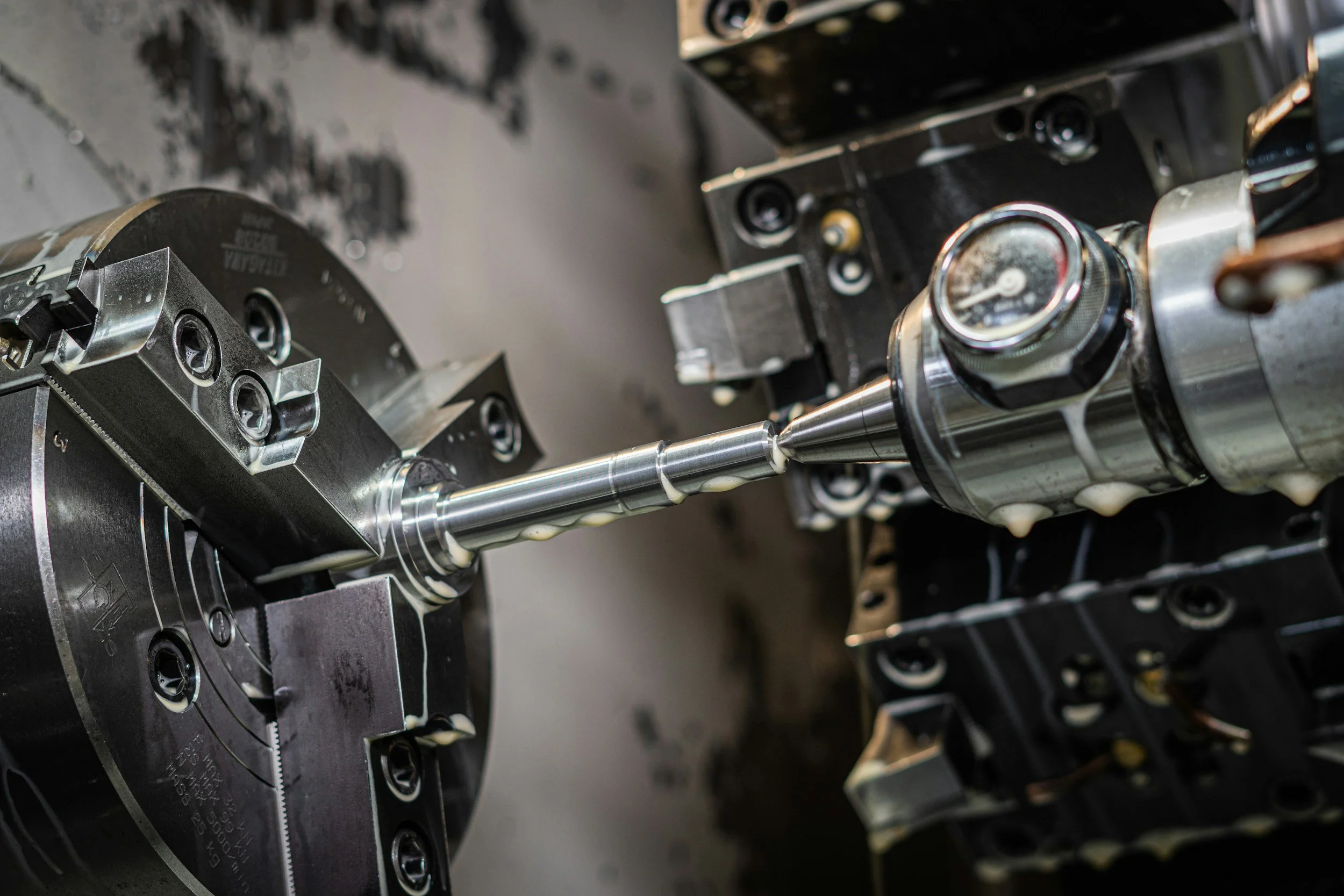

CNC Lathe or Turning Operations

-

Turning Operations, Facing & Threading

The primary function is to perform turning operations to create diameters, tapering, boring and more. It includes cutting the end surface to create a facing, and creating internal and external threads with precise pitch and depth.

-

Grooving, Parting and Tapering

The ability to cut grooves or channels, features like O-ring grooves or snap fit areas. Parting involves cutting off parts from the main workpiece. Tapering is key to providing precise tapered sections in a workpiece, which is useful for parts like shafts or fittings.

-

Reversing Operation, Auto Tool Change and Live Tooling

When enabled we can reverse the spindle direction, for more complex operations. The Auto Tool Changer enables quick and efficient switching between cutting tools, increasing productivity. Live tooling allows for milling, drilling, and tapping operations while the spindle is turning, offering more versatility.